What is the pulley?

by Hi-Tech on Jul.10, 2010, under Mechanics

A pulley, also called a sheave or a drum, is a mechanism composed of a wheel on an axle or shaft that may have a groove between two flanges around its circumference. Maybe most of you are not familiar with it, but it is a very important mechanical part. There is usually a rope, cable, belt, or chain runs over the wheel and inside the groove if present.

What are the pulleys used for? Generally, they are used to change the direction of an applied force, transmit rotational motion, or realize a mechanical advantage in either a linear or rotational system of motion. They can be used in ships, cars, and many other places.

Now, I’d like to introduce a basic usage of pulleys. Most of you know something about cars, but are you knowledgeable about car components? I think few of you can nod your head. Among various components, pulleys can be applied to improve the efficiency of performance. But how do pulleys work? Most of you know the importance of the engine. In a car, the engine may provide more power than just the wheels. Therefore, it is very necessary to improve the working efficiency of the engine. Doing this requires the usage of pulleys. For example, the engine works with the help of a belt and pulley system. Besides, when you wish to do up your car, you should learn something about engine pulleys. This kind of pulleys may sound unfamiliar to most of people. The engine has several belts that drive various parts of the engine, while belts need pulleys so that they can be held in place and drive the parts of the engine properly.

Two or more pulleys together are called a block and tackle. It is also call the rope and pulley systems. The simplest theory of operation for a pulley system assumes that the pulleys and lines are weightless, and that there is no energy loss due to friction. It is also assumed that the lines do not stretch.

Although the above analysis is not complete enough for you to know well about pulleys, you can still learn the basic information about it. I think it will be of some help for you to bear this information in mind.

Article Source: http://EzineArticles.com/?expert=Ling_Lois

Threaded Rods

by Hi-Tech on Jun.10, 2010, under Fasteners

Buying TipsFactors to consider are:

|

- Stainless steel

- Carbon steel

- Alloy steel

- Aluminum

- Brass

- Copper

- Bronze etc.

- Threaded rods are resistant to chemicals.

- These rods are electrically insulating.

- They are non-magnetic.

- They are lightweight.

- They have low thermal conductivity.

- They reduce vibration and abrasion.

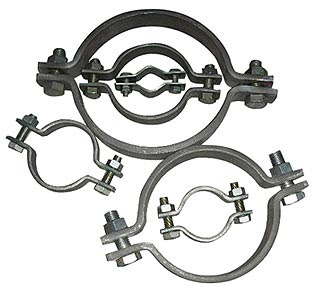

Pipe Clamps

by Hi-Tech on Jun.10, 2010, under Clamps, Pipe Fasteners

Buying Tips

Pipe clamps can be ordered as complete arrangements or separate components. Certain factors to consider to buy pipe clamps are as follows:

- Type of clamp

- Size

- Material

- Finish

- Durability

- Mechanical Properties

- Tensile Strength

- Flexural Yield Strength

- Impact Strength

- Tensile Test

- Thickness

- Modules of Elasticity

- Thermal Properties

- Continuous Service

- Temperature Range

- Electrical Properties

- Volume Resistivity

- Chemical Properties

Pipe clamps usually have one fixed pad, and one adjustable pad. Pipe clamps are constructed using various materials and are available in several configurations with a variety of finishes. Metallic pipe clamps have high impact resistance and various finishes like a brilliant, glossy finish, heat-resistant coatings and epoxy coatings or plain look or hot-dip galvanized or painted.

- Carbon steel

- Mild steel

- Stainless steel

- Alloy steel

- Titanium

- Aluminum

- Thermoplastic elastomer

- Polypropylene

- Polyamide

- PVC etc.

- Rigid Clamps

- U-Bolt Clamps

- Flat Cushion Clamps

- Oval Clamps

- U-Bolt with Cushion Clamps

- P Style Clamps

- Swivel Bolt Clamps

- Diameter

- Outside diameter of pipe

- Cap nut diameter

- Load ability

- Simple to operate

- Easy to install

- Adjustable in small range

- Good appearance

- Temperature range is dependent on the clamp lining being used.

- All pipe clamps are designed to have a very high impact resistance.

- Make for quick, easy pipe installation and layout.

- Shock-absorption

- Vibration dampening

- Noise reducing property

- Heavy torque

- Usually used for large diameter pipes etc.

- The clamp should be mounted directly after the threaded connection or coupling of the piping which in turn protects the connection from vibrations.

- Bends in the line should be clamped on both sides of the pipe bend.

- The pipe line should be clamped directly before and after any in-line valves.

- Proper Torquing of the clamp bolts is very essential.

- Used for fastening and fixing various pipelines whether in construction or industries or buildings etc.

- Provide fast, safe, economic service and installation in piping system.

- Pipe clamps are designed for a wide range of fastening applications.

- These clamps are ideal for suspension of cold or hot pipe lines with heavy load having little or no insulation.

- They are also used for high and even tightening force around the pipe, minimizes leakage.

- The pipe clamps absorb shock, dampen vibration, and reduce noise in plumbing systems.

- They can be used in high temperature applications.